Comparing Air Cooled and Water Cooled Chillers: Which is Better for Your Industrial Needs?

Comparing Air Cooled and Water Cooled Chillers: Which is Better for Industry?

Table of Contents

- 1. Introduction to Chillers in Industrial Applications

- 2. Understanding Chillers: What Are They?

- 3. Types of Chillers: Air Cooled vs. Water Cooled

- 4. Air Cooled Chillers: Features and Advantages

- 5. Water Cooled Chillers: Features and Advantages

- 6. Comparing Air Cooled and Water Cooled Chillers

- 7. Cost Evaluation: Initial Investment vs. Long-Term Savings

- 8. Maintenance Requirements: What You Should Know

- 9. Environmental Impact: Energy Efficiency and Sustainability

- 10. Conclusion: Making the Right Choice for Your Industry

- 11. Frequently Asked Questions (FAQs)

1. Introduction to Chillers in Industrial Applications

In today’s industrial landscape, efficient cooling systems are essential to maintain optimal operational conditions. Among these systems, chillers play a crucial role in regulating temperature across various processes. Choosing the right type of chiller—**air cooled** or **water cooled**—is vital for maximizing efficiency, reducing operational costs, and ensuring sustainability. This guide delves into the characteristics, advantages, and applications of both types of chillers to help you make an informed decision for your industrial needs.

2. Understanding Chillers: What Are They?

Chillers are heat exchange devices that remove heat from a liquid through a vapor-compression or absorption refrigeration cycle. This cooled liquid is then used in various applications such as cooling machinery, maintaining product temperature, or even in HVAC systems for climate control. Understanding the fundamental operation of chillers is critical when evaluating which type best suits your industrial application.

3. Types of Chillers: Air Cooled vs. Water Cooled

There are two primary types of chillers used in industrial settings: **air cooled** and **water cooled**. Each type operates on different principles and is suited to specific applications.

3.1 Air Cooled Chillers

Air cooled chillers rely on ambient air to dissipate heat. They use fans to blow air over coils containing refrigerant, allowing the refrigerant to cool down as it absorbs heat from the process fluid. This type is generally easier to install and requires less space.

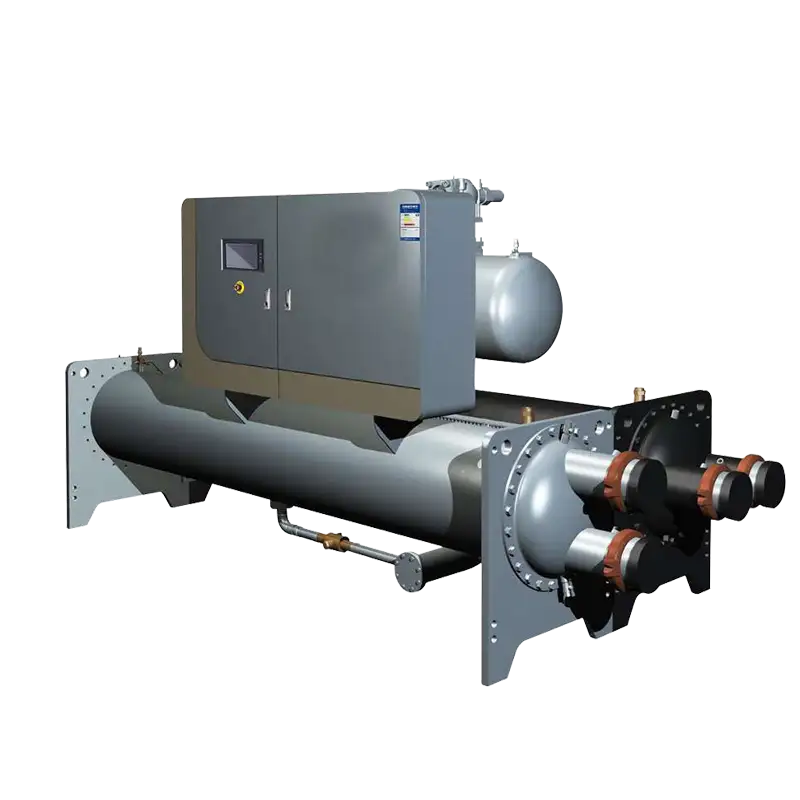

3.2 Water Cooled Chillers

In contrast, water cooled chillers utilize water as a refrigerant cooling medium. These chillers usually necessitate a cooling tower or a body of water to reject heat. They are often more efficient in energy consumption but require more complex installation and maintenance.

4. Air Cooled Chillers: Features and Advantages

Air cooled chillers offer several features that make them appealing for specific industrial applications:

4.1 Simplicity and Flexibility

One of the primary advantages of air cooled chillers is their simplicity. They do not require additional cooling towers or water supply systems, making installation straightforward. This feature allows for flexibility in placement, especially in regions where water availability is limited.

4.2 Lower Initial Investment

Typically, air cooled chillers have a lower upfront cost compared to their water cooled counterparts. This makes them an attractive option for smaller operations or companies that are just starting.

4.3 Reduced Maintenance Requirements

Air cooled chillers require less maintenance since they do not have many moving parts associated with water systems. This can lead to lower operational costs over time.

5. Water Cooled Chillers: Features and Advantages

While air cooled chillers have their merits, water cooled chillers boast several significant benefits:

5.1 Higher Efficiency

Water cooled chillers generally exhibit higher efficiency rates compared to air cooled models, particularly in larger industrial applications. They are more effective at dissipating heat, leading to lower energy consumption.

5.2 Compact Design

These chillers tend to have a more compact design when compared to air cooled chillers, allowing for better space utilization within a facility. This can be crucial in densely populated industrial environments.

5.3 Enhanced Longevity

With appropriate maintenance, water cooled chillers often last longer than air cooled options. The ability to manage heat effectively contributes to a more extended operational lifespan.

6. Comparing Air Cooled and Water Cooled Chillers

When evaluating air cooled and water cooled chillers, several factors must be considered:

6.1 Efficiency

Water cooled chillers usually outperform air cooled chillers in efficiency, especially in larger systems. This is vital for industries with high cooling demands.

6.2 Installation Costs

While air cooled chillers have lower initial costs, water cooled units, though pricier, often offer better long-term savings due to their energy efficiency.

6.3 Space Requirements

Air cooled chillers require more space for proper airflow, whereas water cooled chillers can be more compact. Consideration of available space within your facility is essential.

6.4 Environmental Considerations

Water cooled chillers can have a higher initial environmental impact due to the need for water sources and cooling towers. However, their efficiency can lead to lower overall emissions over time.

7. Cost Evaluation: Initial Investment vs. Long-Term Savings

Cost evaluation is crucial when selecting a chiller type. Air cooled chillers have lower purchase costs, but long-term operational costs can vary significantly.

7.1 Upfront Costs

Air cooled chillers are generally more affordable to purchase and install, making them suitable for businesses with limited budgets.

7.2 Operational Costs

Water cooled chillers, although more expensive initially, can result in substantial energy savings due to their higher efficiency. Analyzing your facility's cooling requirements and energy costs is vital for making the right decision.

8. Maintenance Requirements: What You Should Know

Maintenance is a critical aspect of chiller performance. Understanding the maintenance needs of each type will influence your decision.

8.1 Air Cooled Chiller Maintenance

These chillers require regular cleaning of the coils and fans to ensure effective airflow. Additionally, checking refrigerant levels and system components is essential for optimal performance.

8.2 Water Cooled Chiller Maintenance

Water cooled chillers demand more comprehensive maintenance due to the water systems involved. This includes monitoring water quality, inspecting cooling towers, and ensuring proper flow rates.

9. Environmental Impact: Energy Efficiency and Sustainability

Sustainability is becoming increasingly vital in industrial settings. Evaluating the environmental impact of your cooling system is essential for compliance and corporate responsibility.

9.1 Energy Consumption

Water cooled chillers generally consume less energy, leading to lower greenhouse gas emissions. This aligns with sustainability goals while also reducing utility costs.

9.2 Water Usage

Air cooled chillers require no water, making them suitable for regions facing water scarcity. Water cooled options, while efficient, can strain local water resources if not managed correctly.

10. Conclusion: Making the Right Choice for Your Industry

In conclusion, both air cooled and water cooled chillers offer unique advantages and potential drawbacks. The decision between the two should be based on individual operational needs, budget constraints, and environmental considerations. By thoroughly evaluating factors such as efficiency, cost, maintenance, and sustainability, businesses can select the chiller type that best supports their industrial processes and long-term goals.

11. Frequently Asked Questions (FAQs)

1. Which type of chiller is more efficient?

Water cooled chillers typically offer higher efficiency, especially in larger industrial applications with high cooling demands.

2. What are the installation costs for air cooled chillers?

Air cooled chillers generally have lower installation costs compared to water cooled chillers due to their simpler setup.

3. Do air cooled chillers require more maintenance than water cooled chillers?

No, air cooled chillers typically require less maintenance than water cooled chillers, which have more complex systems.

4. Can I install an air cooled chiller in a water-scarce area?

Yes, air cooled chillers do not require water for operation, making them ideal for regions with limited water resources.

5. How do I determine which chiller type is best for my facility?

Evaluate your facility’s cooling requirements, budget, available space, and environmental impact to make an informed decision on the best chiller type.