A Comprehensive Guide to Industrial Air Cooled Chiller Maintenance

A Comprehensive Guide to Industrial Air Cooled Chiller Maintenance

Table of Contents

- Introduction to Industrial Air Cooled Chillers

- Importance of Regular Maintenance

- Routine Maintenance Tasks for Air Cooled Chillers

- Troubleshooting Common Chiller Issues

- Advanced Maintenance Techniques

- Best Practices for Chiller Care

- When to Call a Professional

- Conclusion

- FAQs about Air Cooled Chiller Maintenance

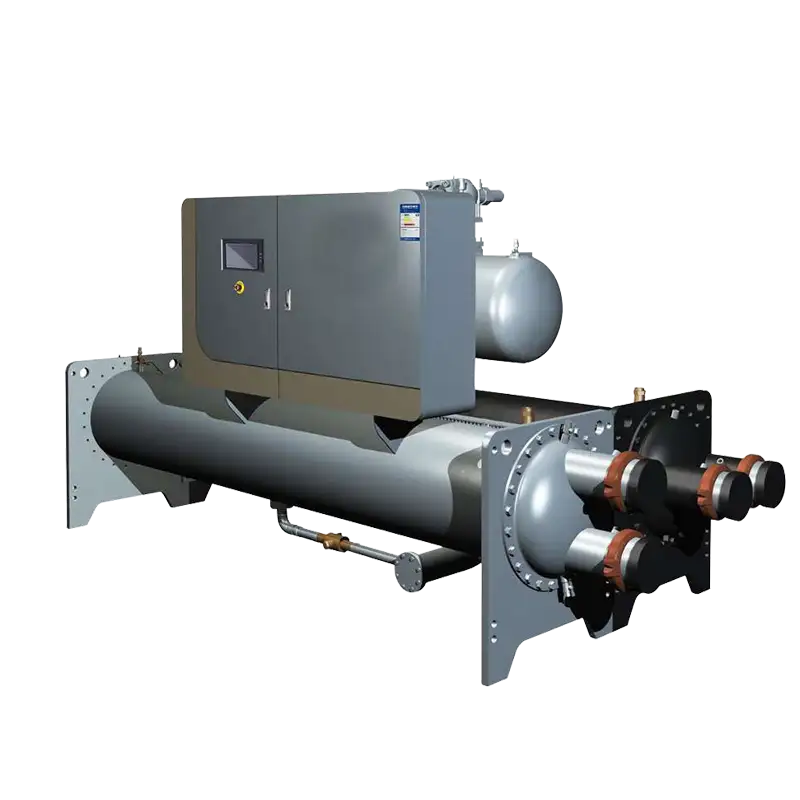

Introduction to Industrial Air Cooled Chillers

Industrial air cooled chillers are essential pieces of equipment used in various applications, from manufacturing processes to climate control in large buildings. They operate by removing heat from a liquid via vapor-compression or absorption refrigeration cycles, making them crucial for maintaining optimal operational temperatures. Understanding how to maintain these systems can prolong their lifespan and enhance their efficiency.

Importance of Regular Maintenance

Regular maintenance of air cooled chillers is vital for several reasons. Firstly, it **ensures optimal performance** by minimizing energy consumption and maximizing cooling efficiency. Secondly, consistent upkeep helps in identifying potential problems before they escalate into costly repairs or downtimes. Lastly, maintaining chillers can significantly extend their operational lifespan, saving organizations money on replacements.

Routine Maintenance Tasks for Air Cooled Chillers

Implementing routine maintenance tasks is crucial for keeping industrial air cooled chillers in peak condition. These tasks can be categorized into **monthly** and **seasonal** tasks.

Monthly Maintenance Tasks

1. **Check and Clean Air Filters:** Dirty air filters can restrict airflow, reducing efficiency. Inspect and clean or replace filters monthly to maintain optimal air circulation.

2. **Inspect Condenser Coils:** Dust and debris can accumulate on condenser coils, hindering heat exchange. Clean the coils to ensure effective operation.

3. **Check Refrigerant Levels:** Low refrigerant levels can indicate leaks. Regularly checking levels helps in identifying issues early.

4. **Monitor Operating Pressures:** Ensure that the operating pressures of the system are within the manufacturer’s specifications. This can help in optimizing performance.

5. **Inspect Electrical Components:** Look for signs of wear or damage in wiring and connections. Promptly address any issues to prevent electrical failures.

Seasonal Maintenance Tasks

1. **Comprehensive System Inspection:** At the beginning of each season, conduct a thorough inspection of the entire system, including compressor, evaporator, and expansion valve.

2. **Check Insulation:** Inspect insulation around pipes and ducts for damage. Replace any worn insulation to prevent energy loss.

3. **Evaluate System Controls:** Ensure that all control systems are operational and calibrated correctly. This includes thermostats and automation systems.

4. **Test Emergency Shutdown Systems:** Verify the functionality of emergency shutdown features to ensure safety and compliance.

5. **Prepare for Seasonal Changes:** Depending on the season, adjust settings and operations to align with the expected load requirements; this ensures efficiency and reliability.

Troubleshooting Common Chiller Issues

Despite regular maintenance, issues may still arise. Here are some common problems and their solutions:

1. **Inadequate Cooling:** This can result from low refrigerant levels, dirty coils, or faulty thermostats. Begin troubleshooting by checking refrigerant levels and cleaning coils.

2. **Unusual Noises:** Strange sounds can signal mechanical issues. Inspect components like the compressor and fans for wear or misalignment.

3. **Frequent Cycling:** If the chiller frequently starts and stops, it may indicate incorrect refrigerant charge or a malfunctioning thermostat. Check these components to rectify the problem.

4. **High Energy Bills:** Unexpected increases in energy costs can suggest inefficiencies. Review maintenance records and consider a comprehensive system evaluation.

5. **Water Leaks:** Water pooling around the unit may indicate drain line blockages or malfunctioning components. Inspect and clear any blockages immediately.

Advanced Maintenance Techniques

For organizations with dedicated maintenance teams, implementing advanced techniques can further enhance chiller performance:

1. **Vibration Analysis:** Regularly monitor vibration levels in the compressor and other components to detect potential failures before they occur.

2. **Thermal Imaging:** Utilize thermal imaging technology to detect hot spots in electrical components or refrigerant leaks, allowing for proactive interventions.

3. **Data Monitoring:** Use IoT sensors to track system performance data in real-time. This can facilitate predictive maintenance, reducing unexpected breakdowns.

4. **System Upgrades:** Consider upgrading control systems and refrigerants to newer, more efficient technologies. This not only improves performance but can also enhance energy efficiency.

Best Practices for Chiller Care

Embracing best practices in chiller maintenance is crucial for sustaining performance and reliability:

1. **Maintain Accurate Records:** Keep detailed maintenance logs documenting all inspections, repairs, and replacements. This aids in identifying recurring issues.

2. **Train Personnel:** Ensure that staff responsible for chiller maintenance are adequately trained in the systems and protocols. Regular training can enhance efficiency and safety.

3. **Schedule Regular Maintenance Checks:** Establish a routine maintenance schedule based on the manufacturer’s recommendations and operational demands.

4. **Engage Professional Services:** For complex systems, consider enlisting professional services for advanced maintenance and repairs. Their expertise can prevent costly errors.

5. **Stay Informed About Regulatory Changes:** Keep abreast of any changes in environmental regulations affecting refrigerants and chiller operations to ensure compliance.

When to Call a Professional

While routine maintenance can be managed in-house, certain situations demand professional intervention:

1. **Complex Repairs:** If sophisticated repairs are needed beyond the capability of in-house staff, it’s best to call in qualified technicians.

2. **System Upgrades:** When upgrading systems or components, professional guidance ensures compatibility and efficiency.

3. **Compliance Inspections:** Engage professionals for mandatory inspections to adhere to industry regulations and standards.

4. **Persistent Issues:** If problems persist despite routine maintenance efforts, expert diagnostics can identify underlying causes.

5. **Performance Optimization:** For organizations looking to enhance efficiency or reduce energy costs, a professional assessment can provide valuable insights.

Conclusion

In conclusion, maintaining an industrial air cooled chiller is essential for ensuring its optimal performance and longevity. By adhering to routine and seasonal maintenance tasks, troubleshooting potential issues, and employing advanced techniques, organizations can safeguard their investment in cooling systems. Understanding when to call in professional help further enhances operational reliability. Regular upkeep not only extends the lifespan of chillers but also contributes to energy efficiency, ultimately leading to significant cost savings.

FAQs about Air Cooled Chiller Maintenance

1. **How often should I perform maintenance on my air cooled chiller?**

Routine maintenance should be conducted monthly, with comprehensive inspections performed seasonally.

2. **What are the signs that my chiller needs immediate attention?**

Signs include inadequate cooling, unusual noises, frequent cycling, high energy bills, and water leaks.

3. **Can I perform maintenance on my chiller myself?**

Basic tasks like filter cleaning and visual inspections can be performed in-house, but complex repairs should be handled by professionals.

4. **How do I know if my refrigerant levels are low?**

Low refrigerant levels can lead to inadequate cooling. Regular checks of refrigerant levels should be part of your maintenance routine.

5. **What are the benefits of advanced maintenance techniques?**

Advanced techniques such as vibration analysis and thermal imaging help detect issues early, optimizing performance and preventing costly repairs.

By following this comprehensive guide, organizations can ensure their industrial air cooled chillers operate efficiently, ultimately leading to enhanced productivity and reduced operational costs.